Components

In order to construct complete quasi-optical and waveguide systems, our group has often needed to develop additional specialised sub-components too. These sub-components are generally key or enabling technologies within the completed systems that we develop, and our work on this is motivated by either a need for components that are not otherwise commercially available or where our performance requirements necessitate the development of custom and bespoke devices with state-of-the-art performance, well beyond that which is available commercially.

The components that we have developed have included feedhorn antennas, quasi-optical Faraday rotators, custom designed lenses, high performance polariser grids, very low reflection quasi-optical loads and a laser activated waveguide switch.

Lenses and focussing mirrors

Lenses and focussing mirrors are essential components in any quasi-optical system. Over the years, we have developed many customised lens and mirror designs for quasi-optical systems, based on designs using both commercial software and modelling and optimisation routines developed within the group. These have included large custom lenses for radar systems, Fresnel zone plate lenses and systems using off axis focussing mirrors.

Polariser grids

Polariser grids are used in quasi-optical circuits for signal routing and as part of optical isolators and circulators when placed around a quasi-optical Faraday rotator. Polariser grids are also used to remove unwanted cross-polarised signals potentially introduced by mirrors and lenses.

Quasi-optical loads

For the HiPER project we needed to develop very low return loss loads to terminate reflections from polariser grids and other optical components within the system at better than -80 dB. For the complete system we needed around 40 of these loads and so a process had to be found to allow for cost effective bulk manufacture whilst also providing state-of-the-art performance. The conical loads that we developed were made from carbon-loaded polypropylene using an injection moulding process.

Laser-activated waveguide switch

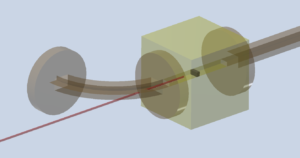

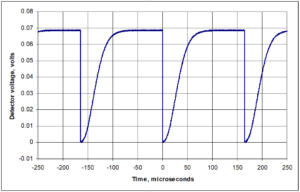

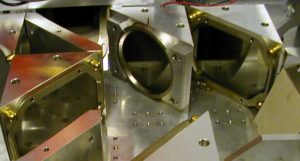

Also for the HiPER project, in order to achieve our goal for exceptionally low deadtime, we needed to develop a fast-activating switch to allow us to block the “dark noise” that is transmitted by the EIK amplifier following the final pulse in a sequence. This switch has to operate on a nanosecond timescale and be capable of handling kW peak powers and there was no commercially available switch to do this. Our solution was to make a laser-activated silicon switch based on the work of Lee et al. In our implementation we use a 1064 nm Q-switched laser to provide trigger pulses to the piece of usually very high resistivity and so low reflection and low loss silicon placed inside the waveguide as shown below. The piece of silicon was carefully machined to be one wavelength thick at 94 GHz. When the 20 µJ pulses from the laser hit the silicon, charge carriers are created which make the silicon behave like a metallic short inside the waveguide, absorbing and reflecting the unwanted dark noise into a waveguide isolator. the graph below shows transmission through the switch with a series of laser flashes causing sharp switching and attenuation as the laser fires, followed by gradually increasing transmission as the charge carriers recombine in the silicon.